Is it Important to Know How Multicyl Cylinders Work?

Not really. Our patented design is like a car engine, internally it is quite complicated but to the user it’s very simple. You just put air in one end using a simple air valve and then you get hydraulic power out of the other end of the cylinder.

What is the Patented Principle?

Known as the ‘flow-by’ principle it allows the two stage pressure intensifier to self-adjust anywhere on the overall stroke. This means the cylinder will stall when it meets resistance greater than the force on the advance stroke.

What is the Benefit of a Two Stage, Self Adjusting Stroke?

For the user there are several benefits: simple air controls; lower air consumption as the power is only produced when you need it. Also there is no need to set the tooling to a precise height (as would be necessary in a mechanical press) as the hydraulic action simply “bottoms out” whenever the resistance is greater.

What Happens Inside the Cylinder During the ‘Flow-By’ Action?

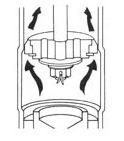

The ram advances using the ‘dashpot’ principle until it meets resistance. Enstrapped oil begins to ‘flow-by’ the low pressure piston by means of precisely controlled clearances as the piston rod is allowed to continue.

The ram advances using the ‘dashpot’ principle until it meets resistance. Enstrapped oil begins to ‘flow-by’ the low pressure piston by means of precisely controlled clearances as the piston rod is allowed to continue.

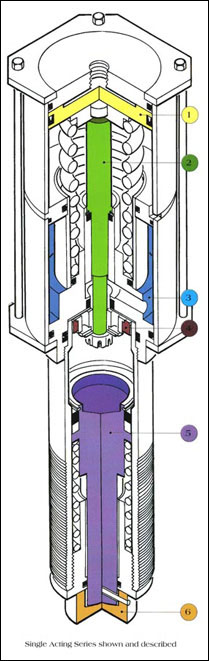

Spherical Pivot Point (MC & XL Series)

The ram piston and striker cap have a spherical pivot point designed to prevent internal side loading. This feature reduces internal wear on seals and bearings and compensates for out of parallel tool conditions. A roll pin allows the striker cap to float and is designed to shear in extreme conditions. Small tools may be mounted upon the end of the spring returned ram piston

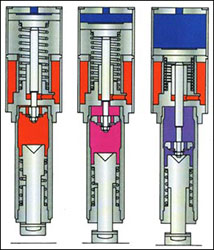

The ‘Flow-By’ Self Adjusting Stroke

Low-pressure (LP) advance stroke. As air pressure is applied to the air piston the HP piston assembly advances. The LP piston valve immediately closes and the ram continues to advance in a full linear fashion until resistance is encountered. Thereupon LP stroke is dissipated by hydraulic ‘flow-by’ principle which permits the air cylinder to continue its advance while the ram remains stationary until the HP stage is reached.

High Pressure (HP) power stroke. The HP piston rod seals the high-pressure chamber. The increased diameter of the HP chamber renders the LP piston powerless. This allows the oil to flow freely within the HP chamber as the LP piston advances. The force on the ram is increased due to the pressure being multiplied by the ratio betweeen the areas of the air piston and the area of the ram piston.

On the return stroke air is exhausted; LP valve immediately opens… allowing oil to flow directly through the piston. Springs return LP piston assembly and arm to ‘rest’ position.

Multicyl’s Products

Start your Multicyl experience with a review of our applications or check out our products or you can get right to work with our interactive SYSTEMATIC™ – Press Selection Tool approach to selecting your Multicyl system.

We believe punching should be simple and cost effective. Read about the most user friendly press in the industry – Press-In-A-Box™, by Multicyl.

Our Systematic™ approach is a step by step tutorial on how to get the most out of our Press-In-A-Box™ approach to press building.

Buying and implementing a press can often be a time consuming and intensive process. With the Multicyl Press-In-A-Box™ approach to press building this is not the case. From the research stage right through to the implementation of your Multicyl press and first production run, the process is quick and simple.

Unitized tooling: A die having its upper and lower members incorporated into a self-contained unit arranged to maintain the die members in alignment.

Why Choose Multicyl?

- Custom designed to suit every hole punching need

- Proven track record

- Extensive product warranty

- Worldwide distribution

What Client’s Say

UniPunch Products has for many years recommended the Multicyl air over oil system to our customers as a reliable method to activate our modular tooling units. Simple to use and maintain, the Multicyl system is capable of performing a wide variety of standard and custom part producing applications. The cylinder and cage designs provided by Multicyl are compatible with the working shut heights of our standard ‘A’ or ‘B’ series c-frame units.